You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

It's been a rough winter in the Pacific..

- Thread starter deepdraft1

- Start date

- Joined

- Jun 21, 2018

- Messages

- 1,481

Wow, SC, must have been 30-40 degree rolls? Thats a lot. On tankers, a 15 degree roll is a lot.

- Joined

- Aug 27, 2010

- Messages

- 5,851

This pic is from the FB page of the USS Bowen. The seas were still heavy but we had just passed through what I was told was the North Wall in the Atlantic. I can't explain it but Google or Bing can. We were on our way to the Caribbean and got slammed. This was my fourth ship and this was the worst sea state I had ever been in. I walked through the ship a couple times checking for injuries and in the bow I was literally walking on the bulkhead. I had to retreat to sick bay and my junior HM and I tied ourselves into chairs and rode it out. The 5 inch 54 was turned facing the bridge to protect the barrel and other things. The soft patch which is usually facing aft was blown out in doing this. Sea water entered the mount and damaged parts and wiring in the mount and carrier room. We pulled into Mayport for an inspection and repairs. We spent about three days there and got underway with tech reps to continue fixing things. We were actually able to make tin can go boom when we got to Vieques.

I can explain the North Wall effect in detail but will be brief. The North Wall is the effect of the Gulf Stream crossing the Atlantic after it turns East (toward England) from the US Atlantic Coast. The point where it turns East moves North and South with the seasons and you can actually see when it passes an area on the coast if you monitor daily reports of ocean temperatures in the Beach Reports. The effect of the warm Gulf Stream crossing through colder Atlantic waters is that storms "ride" along the warmer water and heated air above it. These storms commonly cause high seas (waves) and winds along the North Wall. Many folks have read about the "Bermuda Triangle", it is now fairly widely believed that much of the reported "stuff" is at least partially due to that same North Wall effect.

- Joined

- Aug 27, 2010

- Messages

- 5,851

My LPD did over 45 degree rolls in the Med on our "Beirut cruise". Big Storms, in the EastMed and no real shelter we could take.Wow, SC, must have been 30-40 degree rolls? Thats a lot. On tankers, a 15 degree roll is a lot.

- Joined

- Jun 21, 2018

- Messages

- 1,481

Even the very seasoned would eventually get sick in those conditions.My LPD did over 45 degree rolls in the Med on our "Beirut cruise". Big Storms, in the EastMed and no real shelter we could take.

- Joined

- Apr 25, 2018

- Messages

- 5,546

Snipes were talking about being afraid of water going down the mack. Knox frigates have a mack which is a combo stack and mast.Wow, SC, must have been 30-40 degree rolls? Thats a lot. On tankers, a 15 degree roll is a lot.

- Joined

- Jun 21, 2018

- Messages

- 1,481

That reminds me, I currently help an Admiralty firm with litigation support - commercial ships, tugs, ATBs, ITBs, etc. typically large incidents. Often we see machinery casualties when a ship or large tug experiences a significant list. Lube Oil often is not fully contained. This was a factor in the tragic El Faro case.Snipes were talking about being afraid of water going down the mack. Knox frigates have a mack which is a combo stack and mast.

Last edited:

- Joined

- Sep 27, 2008

- Messages

- 20,633

I recognize we are in a maritime thread, but the ocean doesn’t distinguish.

I knew I had seen this clip in the last few years. Salutes to the sailors working forward to execute the unrep evolution, kudos to the bridge teams doing the side-by-side ship driving in those seas. The hard labor is being done by the deck crews on each ship and their supervisors. Dangerous, cold, wet.

For those readers who don’t know what’s going on, “unrep” is underway replenishment, passing gas at sea . Other things, and people in a basket, can get passed too. It’s akin to driving a Suburban and a Corolla next to each other on the freeway at speed, passing things via a line through the windows.

. Other things, and people in a basket, can get passed too. It’s akin to driving a Suburban and a Corolla next to each other on the freeway at speed, passing things via a line through the windows.

I knew I had seen this clip in the last few years. Salutes to the sailors working forward to execute the unrep evolution, kudos to the bridge teams doing the side-by-side ship driving in those seas. The hard labor is being done by the deck crews on each ship and their supervisors. Dangerous, cold, wet.

For those readers who don’t know what’s going on, “unrep” is underway replenishment, passing gas at sea

- Joined

- Jun 21, 2018

- Messages

- 1,481

Yikes! Finished with the water on deck.I recognize we are in a maritime thread, but the ocean doesn’t distinguish.

I knew I had seen this clip in the last few years. Salutes to the sailors working forward to execute the unrep evolution, kudos to the bridge teams doing the side-by-side ship driving in those seas. The hard labor is being done by the deck crews on each ship and their supervisors. Dangerous, cold, wet.

For those readers who don’t know what’s going on, “unrep” is underway replenishment, passing gas at sea. Other things, and people in a basket, can get passed too. It’s akin to driving a Suburban and a Corolla next to each other on the freeway at speed, passing things via a line through the windows.

- Joined

- Sep 27, 2008

- Messages

- 20,633

We actually love those videos if we are not there. The stuff of many a great sea story.All of you are crazy.

There are dozens of videos on YouTube “ships in heavy seas.” The crazy ones are the massive ships with waves over the bow, such as aircraft carriers.

Of course, you can still the adrenaline rush by finding videos of crystal blue seas, beautiful skies, dolphins surfing the bow wave, whales breaching, a peaceful and gentle sea, capped off with a gorgeous sunset and green flash.

Last edited:

- Joined

- Jun 21, 2018

- Messages

- 1,481

Puts an "OSCAR" drill in a whole different perspective!I recognize we are in a maritime thread, but the ocean doesn’t distinguish.

I knew I had seen this clip in the last few years. Salutes to the sailors working forward to execute the unrep evolution, kudos to the bridge teams doing the side-by-side ship driving in those seas. The hard labor is being done by the deck crews on each ship and their supervisors. Dangerous, cold, wet.

For those readers who don’t know what’s going on, “unrep” is underway replenishment, passing gas at sea. Other things, and people in a basket, can get passed too. It’s akin to driving a Suburban and a Corolla next to each other on the freeway at speed, passing things via a line through the windows.

I understand that merchant ships are run with a similar command structure to Navy ships. So, my question is directed towards all knowledgeable mariners here. In a Faro situation when the captain appears to be wrong in the eyes of the rest of the crew but won't yield, what can be done? I'm inquiring specifically about weather conditions that pose a direct threat to the Ship and the crew.

As a youngster, I've briefly learned about the circumstances and rules for disobeying an order (more on that with 2/1/C law and leadership). Presumably, disobeying a captain who is on the bridge with you is vastly different from a ground officer disobeying an order from someone miles away.

As a youngster, I've briefly learned about the circumstances and rules for disobeying an order (more on that with 2/1/C law and leadership). Presumably, disobeying a captain who is on the bridge with you is vastly different from a ground officer disobeying an order from someone miles away.

- Joined

- Jun 21, 2018

- Messages

- 1,481

Excellent question: I will answer for the Merchant Ship, for Navy, someone else can better answer. Marchant Ships over 500 Gross Tons, have to put a Safety Management System (SMS) in place. The SMS is audited internally, and externally by Class (i.e. ABS, Lloyds, DNV). The ISM Code (US Law for Safety Management Systems-word for word the same as internatnational regulations for shipping SOLAS), require a "Designated Person", That person is Ashore and can be contacted by ANY member of the crew when they thing there is s serious violation or hazardous situation. The junior officers on El Faro could have tried that...but it needs to be done early. The EL Faro Master contacted the DP, however, too late for DP to take effective actions. It's more complicated that that...but thats a summary for you.I understand that merchant ships are run with a similar command structure to Navy ships. So, my question is directed towards all knowledgeable mariners here. In a Faro situation when the captain appears to be wrong in the eyes of the rest of the crew but won't yield, what can be done? I'm inquiring specifically about weather conditions that pose a direct threat to the Ship and the crew.

As a youngster, I've briefly learned about the circumstances and rules for disobeying an order (more on that with 2/1/C law and leadership). Presumably, disobeying a captain who is on the bridge with you is vastly different from a ground officer disobeying an order from someone miles away.

Last edited:

- Joined

- Jan 21, 2009

- Messages

- 580

@cb7893, actually one can determine the weight of the ship and her cargo by observing her draft.. and yes, there are a few things to take in to consideration when making that determination.. Density of the water the ship's floating in, being one.. hog or sag of the hull, being another and list on the ship being a third. Once you know the mean draft you can go to your hydrostatic tables and look up the corresponding displacement tonnage.. You can always load deeper in fresh or brackish water than in saltwater. The difference between a ships freshwater draft and her saltwater draft is known as the 'freshwater allowance'. On my ship we used to go up the Yangtse River to Shanghai to load for the west coast. The water at the loading berth was brackish.. So after we got tied up the Chief Mate would do a 'water cut' and determine the water density.. Generally it was around 1.012. [freshwater is 1.000 and saltwater is 1.025]. My ship had a FWA of 8 inches.. So taking 1.012/1.025 x 8" gave us the amount of additional draft we could load to deeper than our summer saltwater marks. It was roughly 4 inches.. Depending on the size of the ship that can be a lot of cargo.. Weight of fuel is determined using the ship 'tank tables'.. Tanks are gauged by sounding them to determine the ullage. The ullage figure is looked up in the tables to get the corresponding number of barrels of oil that are in the tank. Then the calculation is barrels divided by barrels per ton to get the weight.. The weight of the ballast or freshwater [potable water] is done much the same way; tanks are sounded to get the innage and that sounding is looked up in the ballast or FW tank tables to determine the weight.That's a great picture.

I should have qualified my question by specifying loaded vs. empty reefers. I would assume ballast would be an issue.

I read something once, by a reporter who sailed on a dry bulk carrier for several months. One of the most interesting things he described was the negotiation with the folks (pardon my lack of terminology) over the exact weight of the cargo. One can't weigh a ship the way one weighs a truck loaded and then unloaded and figure the difference. Not only was the weight figured on the basis of the draft, but also the water temperature and salinity at the point of loading vs. the point of unloading. I don't remember how they figured the weight of fuel in the tanks. Maybe that wasn't significant.

Thanks to all for answering my dumb questions. I'm the guy at the cocktail party you wish you hadn't started talking to.

What you said about weighing truck loads is correct. Going in the truck, chassis and container are all weighed together at the gate.. When the truck and chassis leave the terminal it's weighed again and that weight is subtracted from the entry weight.. which leaves the weight of the container. The stowage coordinators/cargo planners take it from there. They have the vessels tankage information in their computers and they begin to build the load out. It's fairly complicated and computers do much of the number crunching.. There's still quite a bit the planners have to take into account like Dangerous & Hazardous [D&H] cargo segregation, reefer plug location, cargo discharge ports, cargo lashing requirements, hatch cover clearance of high cubic container stacks in the holds, as well as vessel stability, trim, draft and even hull stresses.. Once the load is finalized, the computer load file is given to the Chief Mate who downloads it into 'stability and trim' program on the ships computer and double checks the numbers. If it all looks good you sail and you're off the next port in the rotation..

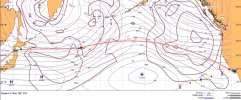

Before taking departure the Master downloads forecast files for the onboard weather program and then runs an 'optimum route' on his computer.. Hopefully the forecast holds up and the ship has a smooth passage.. At my old company we used to use a program called Bon Voyage developed by Applied Weather Technology Inc. Here's what an initial 'optimized' routing looks like for a December trans-Pacific eastbound passage.. I would download updated forecast files daily via satellite from BV then re-run an optimization and 'fine tune' the route as necessary..

Sorry about the 'long winded' response, but hopefully it gives you a little deeper understanding of how your running shoes got here from China.. Cheers!

- Joined

- Jun 21, 2018

- Messages

- 1,481

And dont forget about the Chief Engineers "sleeve barrels"....ha ha. Most of my Chief's would tell me the real figures....this way we could avoid "Deadfreight", a big deal on tankers that are loaded "to draft".@cb7893, actually one can determine the weight of the ship and her cargo by observing her draft.. and yes, there are a few things to take in to consideration when making that determination.. Density of the water the ship's floating in, being one.. hog or sag of the hull, being another and list on the ship being a third. Once you know the mean draft you can go to your hydrostatic tables and look up the corresponding displacement tonnage.. You can always load deeper in fresh or brackish water than in saltwater. The difference between a ships freshwater draft and her saltwater draft is known as the 'freshwater allowance'. On my ship we used to go up the Yangtse River to Shanghai to load for the west coast. The water at the loading berth was brackish.. So after we got tied up the Chief Mate would do a 'water cut' and determine the water density.. Generally it was around 1.012. [freshwater is 1.000 and saltwater is 1.025]. My ship had a FWA of 8 inches.. So taking 1.012/1.025 x 8" gave us the amount of additional draft we could load to deeper than our summer saltwater marks. It was roughly 4 inches.. Depending on the size of the ship that can be a lot of cargo.. Weight of fuel is determined using the ship 'tank tables'.. Tanks are gauged by sounding them to determine the ullage. The ullage figure is looked up in the tables to get the corresponding number of barrels of oil that are in the tank. Then the calculation is barrels divided by barrels per ton to get the weight.. The weight of the ballast or freshwater [potable water] is done much the same way; tanks are sounded to get the innage and that sounding is looked up in the ballast or FW tank tables to determine the weight.

What you said about weighing truck loads is correct. Going in the truck, chassis and container are all weighed together at the gate.. When the truck and chassis leave the terminal it's weighed again and that weight is subtracted from the entry weight.. which leaves the weight of the container. The stowage coordinators/cargo planners take it from there. They have the vessels tankage information in their computers and they begin to build the load out. It's fairly complicated and computers do much of the number crunching.. There's still quite a bit the planners have to take into account like Dangerous & Hazardous [D&H] cargo segregation, reefer plug location, cargo discharge ports, cargo lashing requirements, hatch cover clearance of high cubic container stacks in the holds, as well as vessel stability, trim, draft and even hull stresses.. Once the load is finalized, the computer load file is given to the Chief Mate who downloads it into 'stability and trim' program on the ships computer and double checks the numbers. If it all looks good you sail and you're off the next port in the rotation..

Before taking departure the Master downloads forecast files for the onboard weather program and then runs an 'optimum route' on his computer.. Hopefully the forecast holds up and the ship has a smooth passage.. At my old company we used to use a program called Bon Voyage developed by Applied Weather Technology Inc. Here's what an initial 'optimized' routing looks like for a December trans-Pacific eastbound passage.. I would download updated forecast files daily via satellite from BV then re-run an optimization and 'fine tune' the route as necessary..

View attachment 7984

Sorry about the 'long winded' response, but hopefully it gives you a little deeper understanding of how your running shoes got here from China.. Cheers!

- Joined

- Aug 27, 2010

- Messages

- 5,851

Add to the "passing things via a line through the windows" the ending "For Hours at a time.For those readers who don’t know what’s going on, “unrep” is underway replenishment, passing gas at sea. Other things, and people in a basket, can get passed too. It’s akin to driving a Suburban and a Corolla next to each other on the freeway at speed, passing things via a line through the windows.

I remember one very memorable unrep in the Eastern Med that took 6 or so hours, partly due to amount of fuel needed and partly due to equipment and eventually weather issues. It was high 50's or so at the start and we were wearing light jackets but by the end, we were in a near blizzard with high crosswinds. We'd already had to do a 180 degree turn WHILE UNREPPING (in tandem with the tanker) as we ran out of sea room and were extremely cold and wet on the bridge and at the replenishment stations.

Heatherg21

USNA '24 Mom BGO Bacon Lover Dog Lover

- Joined

- Jun 26, 2019

- Messages

- 5,629

I just ordered a first edition copy of this from Alibris. I was shocked to see one on Amazon for over $600. Too pricey for me. Looking forward to reading it.For anyone interested in a graphic account of battling heavy weather at sea, I highly recommend this book.. The author was the Captain of the USS DEWEY, one of Admiral Halsey's 'small boys' that survived what is arguably the 'Mightiest Storm in Naval History'

View attachment 7978

The final paragraph in the book preface is sobering.. and sums up the experience the men of the DEWEY went through...

‘For the small, wet, and bedraggled group of men who clung for their lives to the gale ravaged bridge of the USS DEWEY, the typhoon was a traumatic, soul searing, and humbling experience. It left its indelible imprint on each of them. Just before deliverance was assured, when every giant roll appeared to be their last, and the wind’s roar was almost deafening, there came a stillness as the tempest drew its breath. In that moment of silence the voices of those men were heard intoning the words of the Navy Hymn:

'Oh hear us when we cry to Thee For those in peril on the sea.’

- Joined

- Jan 21, 2009

- Messages

- 580

@Heatherg21, the 3rd Fleet encounter with Typhoon Cobra was also the inspiration for the climax in Herman Wouk's novel 'The Caine Mutiny'..I just ordered a first edition copy of this from Alibris. I was shocked to see one on Amazon for over $600. Too pricey for me. Looking forward to reading it.

Heatherg21

USNA '24 Mom BGO Bacon Lover Dog Lover

- Joined

- Jun 26, 2019

- Messages

- 5,629

Nice, now I'm going to have to read that one, too. I like adding things to my reading list. Thank you!@Heatherg21, the 3rd Fleet encounter with Typhoon Cobra was also the inspiration for the climax in Herman Wouk's novel 'The Caine Mutiny'..

View attachment 7987